Swift Tips

Battery Care

- Add water as needed – do not overfill. (only water a fully charged battery)

- Always keep electrolyte level above separator protectors.

- Keep vent caps tightly in place.

- Charge battery on properly matched charger.

- Allow battery to cool down before placing it back into service.

- Keep battery top clean, dry and free of foreign objects.

- Keep battery and truck cover open during charging.

- Batteries produce explosive gases, keep flame and sparks away from battery.

- Do not discharge beyond 80% (1.140-1.160 SP.GR.)

- Report any problems or damage, minor problems can become major ones.

- Good battery care is not a luxury, it’s a necessity!!

Battery Room Safety

Here are a few tips to keep in mind when handling batteries and also when you are in and around battery rooms:

- Batteries are a shock hazard. Before touching the battery, be sure to discharge static electricity by touching a grounded surface away from the batteries. Always use protective insulating equipment such as; gloves, shoes, and eye protection at a minimum. Never wear conductive jewelry such as rings, bracelets, watches, etc. when working on batteries.

- Batteries produce hydrogen gas which can be explosive. Make sure the rooms where your batteries are located have adequate ventilation, so that hydrogen gas does not accumulate. If you smell an odor of rotten eggs this is likely an indication of a charging issue or a bad cell.

- This should go without saying, but do not smoke, create a spark, or have open flames in an area near batteries!

- Batteries contain sulfuric acid, which can cause burns. If electrolyte makes contact with your skin, remove contaminated clothing and rinse area thoroughly with water. If eye contact with electrolyte has occurred, flush for a minimum of 15 minutes and seek medical attention.

- Keep your eyes open for anything outside of the ordinary. Battery jars can crack and leak electrolyte, so always do a good visual inspection of your cells to make sure this isn’t the case. Containers can bulge due to overheating, a container with this issue might be hot to the touch. Also, battery connectors can become discolored from overheating or improper connections. These are just a few ways to spot potential problems before they can get worse.

Cold Weather Tips: Batteries

During the cold winter months, it is critical to remember how temperature affects battery health. Heat accelerates the chemical activity in a battery, while cold temperatures will slow it down. The normal lead acid battery operating temperature is 77 degrees Fahrenheit. Colder temperatures during the winter result in colder temperatures for many battery strings. The drop in overall temperature can increase battery life, decrease performance, decrease water usage, and decrease maintenance requirements. The biggest concern of those is your battery’s performance. You can drop 10% or more of the capacity of your battery for electrolyte temperatures 60 degrees Fahrenheit and 20% or more for 40 degrees Fahrenheit.

Many battery users are concerned about the electrolyte in a battery freezing. While that is a possibility, it takes extreme weather conditions to do so. A typical 1.215 specific gravity battery has a freezing point of around -32 degrees Fahrenheit, while a 1.250 gravity battery is around -61 degrees Fahrenheit.

Below are tips for minimizing the effects of cold weather on your battery systems:

- Check your heating system in the battery room or cabinet (if available) and make sure that it is functioning properly. Lead acid batteries like to be in an environment of 77 degrees Fahrenheit which can be a challenge during the winter. For VLA batteries, check the temperature of your electrolyte to determine battery temperature, as it can be different from ambient temperature. For VRLA batteries check the temperature of the battery at the negative post.

- Lower temperatures condense the electrolyte of the battery and as a result, it concentrates the electrolyte. As such, electrolyte temperature below 77 degrees Fahrenheit will result in approximately .001 higher voltage reading per 3 degrees Fahrenheit. A typical 1.215 gravity battery at 77 degrees Fahrenheit would be 1.222 at 56 degrees Fahrenheit. Keep an eye on this during your winter month PMs. A high gravity reading may raise concerns, but in reality, this is very normal.

- Temperature compensated charging is a great tool you can use to help alleviate some of the cold effects. Some newer chargers come equipped with Temperature Control Sensors on the batteries. This allows for the charge voltage on the batteries to be reduced or increased based on the temperature at the sensor point. Please reach out to us with the charger model and serial number if you aren’t sure if your charger has this functionality.

- If you do not have temperature-controlled charging as a feature, you can manually adjust charger float and equalize voltage. This is much more challenging to keep up with as you won’t know the temperature daily to adjust the charger to. Most recommended float charge voltages are based on a battery sitting in an environment that is 77 degrees Fahrenheit. Consult your manufacturer’s operation manual for the recommended adjustment based on ambient temperature.

Example: A C&D VLA battery that normally operates at 77 degrees Fahrenheit might have a float voltage of 2.20 volts per cell. The corrected float voltage at 56 degrees Fahrenheit would be 2.228 volts per cell. So, a 60-cell string that normally floats at 132VDC would now be adjusted to 133.68VDC to improve cold weather performance.

Source: C&D Standby Battery Vented Cell Installation & Operating Instructions (RS-1476)

Warm Weather Tips: Stationary Batteries

During the warm summer months, it is critical to remember how temperature affects battery health. Heat accelerates the chemical activity in a battery, while cold temperatures will slow it down. The normal battery operating temperature is 77 degrees Fahrenheit.

Warmer temperatures during the summer result in higher temperatures for many battery strings. These increases can result in shortened life, increased performance, increased internal discharge, and increased water usage. This reduction in life is approximately 50% for every 15-degree Fahrenheit rise. This is based on average annual temperature, not simply if your battery room reaches 92 degrees Fahrenheit one time.

Example: Batteries with a normal service life of five years at 77 degrees Fahrenheit will only last two and a half years at 92 degrees Fahrenheit. During the summer you can drastically age your batteries by not keeping them in a temperature-controlled environment.

Below are tips for minimizing the effects of heat on your battery systems:

- Check your HVAC system in the battery room or cabinet (if available) and make sure that it is functioning properly. Lead Acid batteries like to be in an environment of 77 degrees Fahrenheit which can be a challenge during the summer. For VLA batteries check the temperature of your electrolyte to determine battery temperature as it can be different from ambient temperature. For VRLA batteries check the temperature of the battery at the negative post.

- Temperature compensated charging is a great tool you can use to help alleviate some of the heat effects. Some newer chargers come equipped with Temperature Control Sensors on the batteries. This allows for the charge voltage on the batteries to be reduced or increased based on the temperature at the sensor point. Please reach out to us with the charger model and serial number if you aren’t sure if your charger has this functionality.

- If you do not have temperature-controlled charging as a feature, you can manually adjust charger float and equalize voltage. This is much more challenging to keep up with as you won’t know the temperature daily to adjust the charger to. Most recommended float charge voltages are based on a battery sitting in an environment that is 77 degrees Fahrenheit. Consult your manufacturer’s operation manual for the recommended adjustment based on ambient temperature.

Example: A C&D VLA battery that normally operates at 77 degrees Fahrenheit might have a float voltage of 2.20 volts per cell. The corrected float voltage at 87 degrees Fahrenheit would be 2.172 volts per cell. So, a 60 cell string that normally floats at 132VDC would now be adjusted to 130.30VDC to improve the battery health.

Source: C&D Standby Battery Vented Cell Installation & Operating Instructions (RS-1476)

Does Load Testing Shorten Lead Acid Battery Life?

The short answer is no, Load Testing does not shorten a battery’s life. The longer answer is that it also depends on how the battery is treated!

THE FACTS

- Frequent charge/discharge cycles will accelerate the battery aging and performance degradation.

- Battery manufacturers don’t recommend excessive testing of their batteries per their Operation Manuals. It is unlikely that testing is needed more often than every 12 months to verify battery capacity. They do allow for a monthly “transfer test” to verify system load transfer if needed.

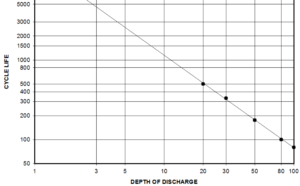

- Since Stationary Batteries are typically in float applications, cycle data isn’t often provided. A battery can handle a certain amount of cycles and that is dependent on the Depth of Discharge (DOD). The deeper the discharge, the less cycles a battery can handle.

- Example: See graph for standard C&D Technologies Vented Lead Acid discharging cycles. 100 cycles at 80% DOD, 190 cycles at 50% DOD, 500 cycles at 20% DOD, etc.

- If you perform Load Testing per IEEE it is likely that you are working under the “Performance Test” guidelines.

- The IEEE Performance Test requires testing within the first two years of a batteries life and then every 25% of its life after that until a battery shows signs of degradation or reaches 85% of its service life. Once a battery shows signs of degradation or reaches 85% of its services life the recommendation is to Load Test annually.

- Example: C&D VLA batteries have a 20-year service life. This would mean tests are likely to be performed at years 2, 7, 12, 17, 18, and 19.

BOTTOM LINE

- In a worst case scenario, if your VLA batteries were load tested 10 times to 80% DOD (1.75 volts per cell) in its life and the you average one outage per year at 80% DOD, that only equals out to 30 discharges of a VLA battery.

- Based on this chart, a C&D VLA battery can handle about 100 cycles at 80% DOD. Performing 10 Load Tests over its life and allowing for one outage per year doesn’t begin to scratch the surface of what these batteries can handle!

Need Help? We sell and service thousands of products.